About us

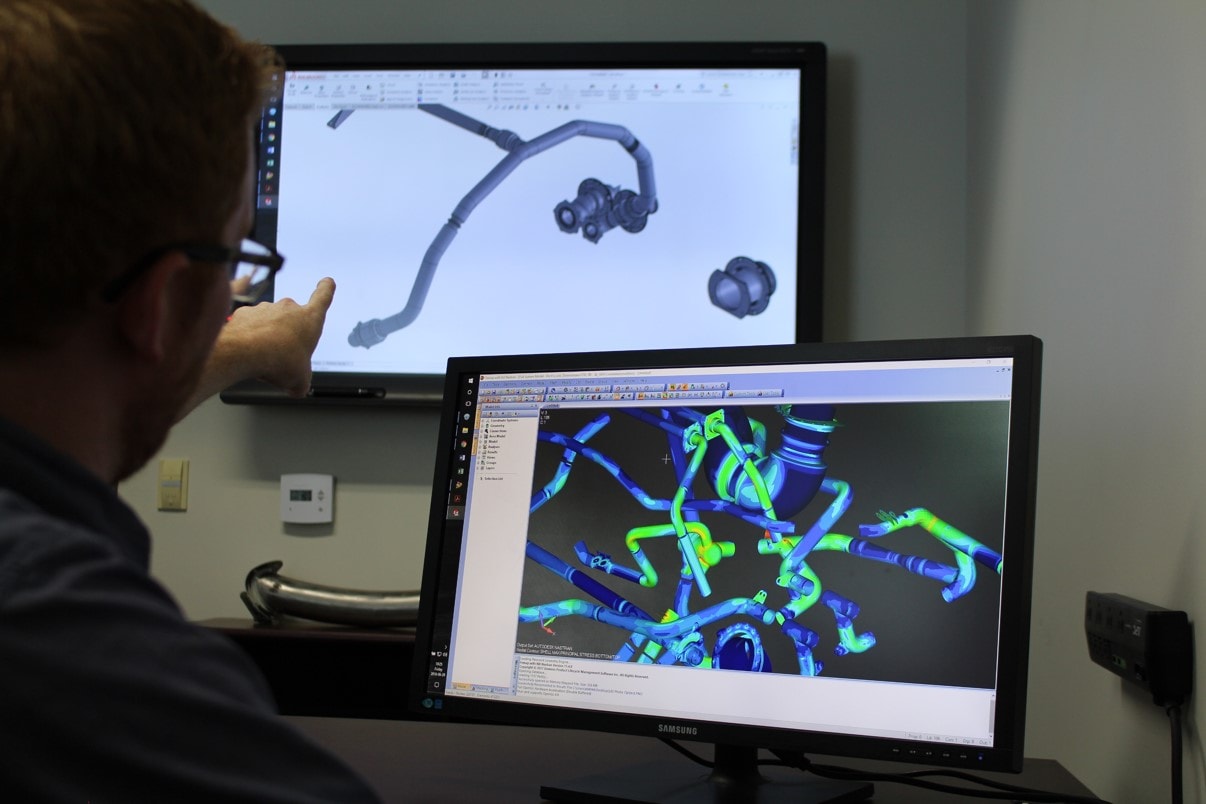

The SSP Engineering Lab is an A2LA Accredited testing laboratory focusing on the testing, development, and qualification of aircraft hardware. This focus has allowed the testing facility and its members to have a greater understanding in systems specialized for aircraft usage, and ultimately set it apart from other competing testing facilities. Our facility specializes in:

– Vibration Testing

– Mechanical Shock Testing

– Fire Proof/Resistance Testing

– Temperature and Humidity Testing

– Continuous Flow Testing

– Static Pressure Testing

– Tensile Testing

– Fatigue Testing

The SSP Engineering Lab has a talented group of members with a range of experience allowing the lab to specialize in a range of complex tests. Our test technicians have over 50 years of combined product qualification testing experience, and possess a fundamental understanding of standard testing requirements and guidelines.

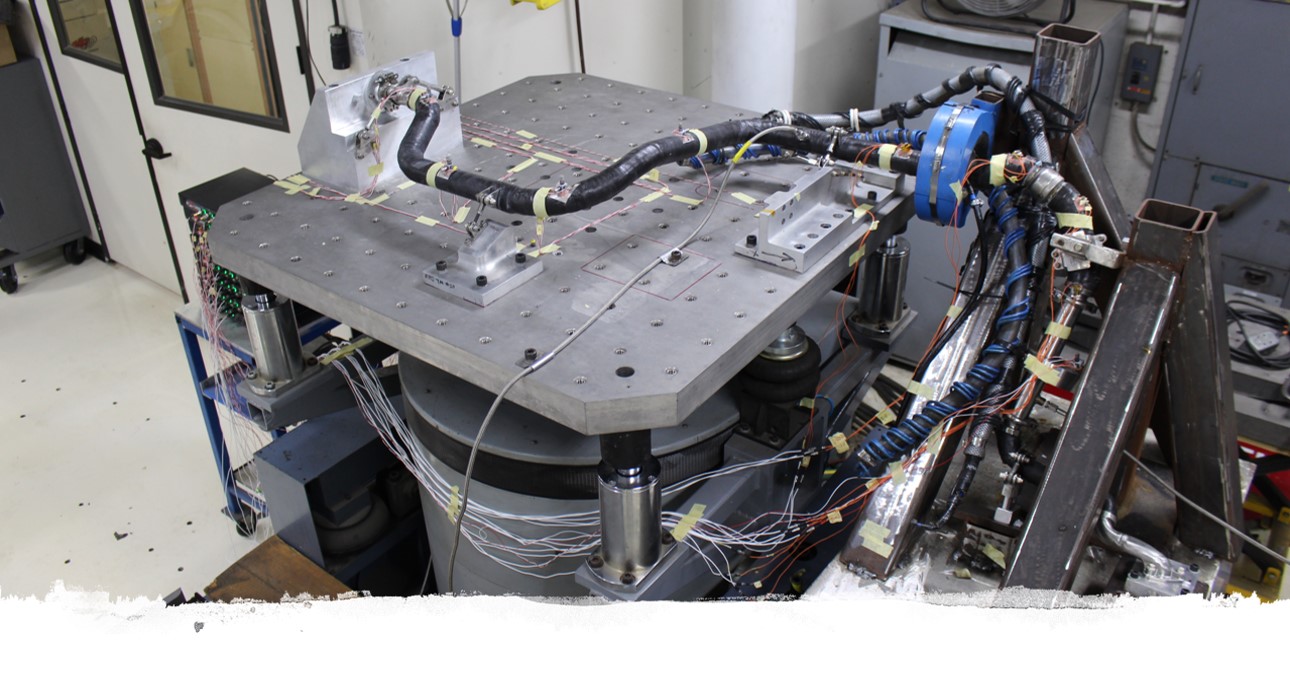

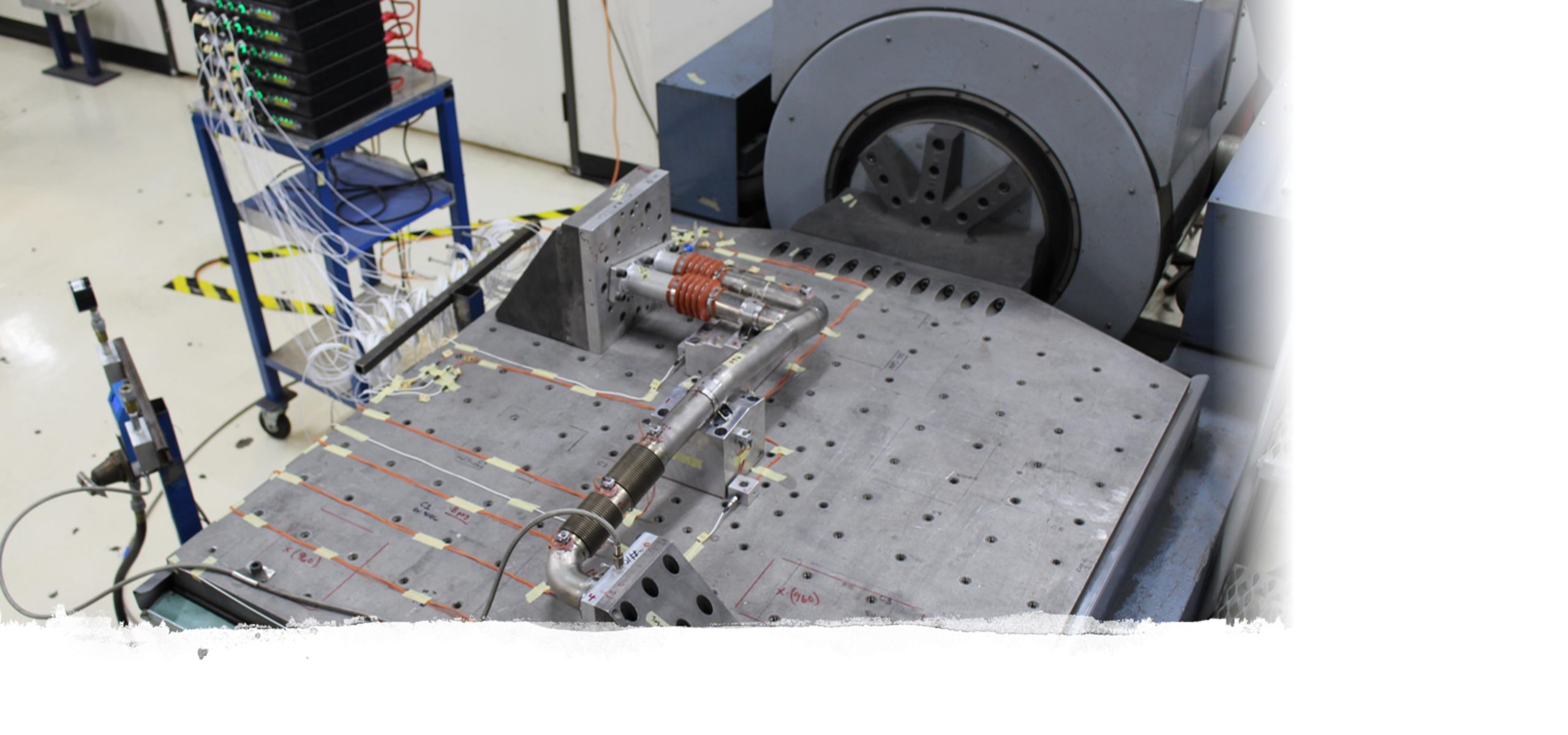

Vibration Testing Services

– Random

– Sine

– Random on Random

– Sine on Random

– Active Resonance Search

– Resonance Dwell

– Engine Blade-Out / Windmilling

– Operational Shock / Crash Safety

Specifications:

– Max vibration force: 20,000 lbf (89 kN)

– Max stroke: 3 in pk-to-pk

– Max velocity: 70 in/s

– Frequency range: 2 – 2000 Hz

– Max slip plate / head expander size: 48 in x 48 in

– 32 channels monitoring / recording

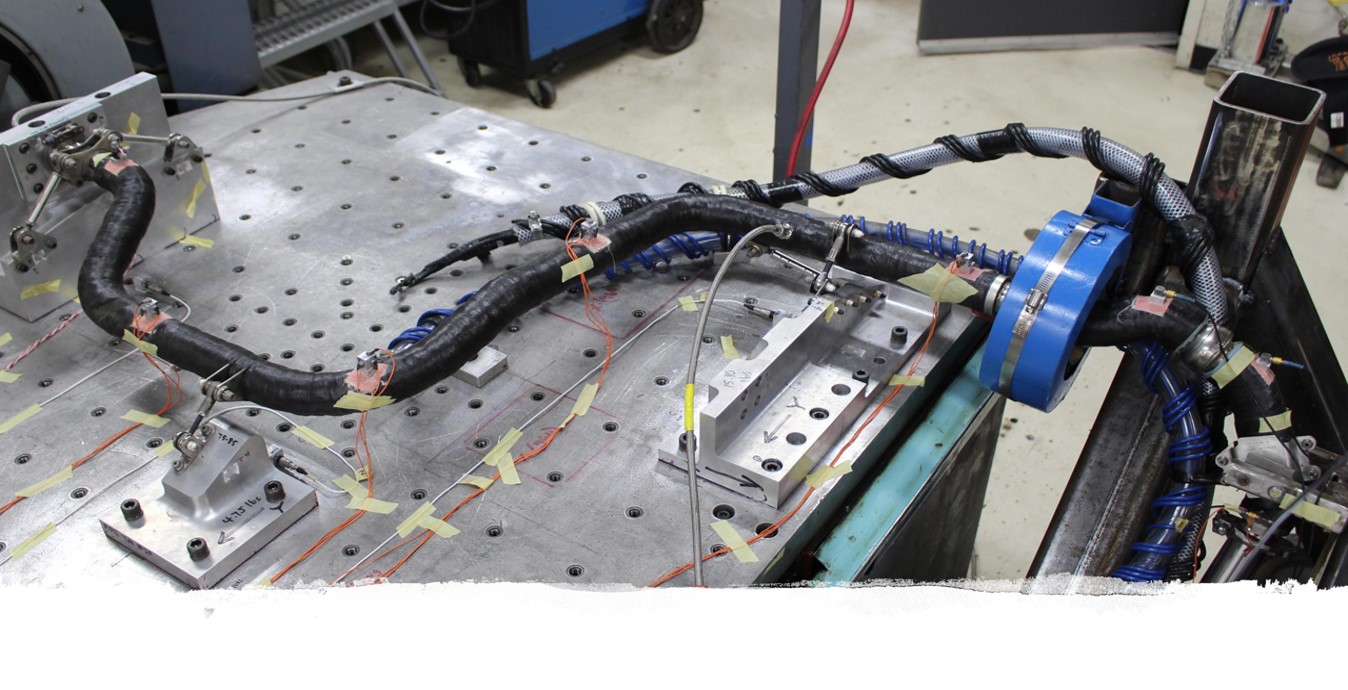

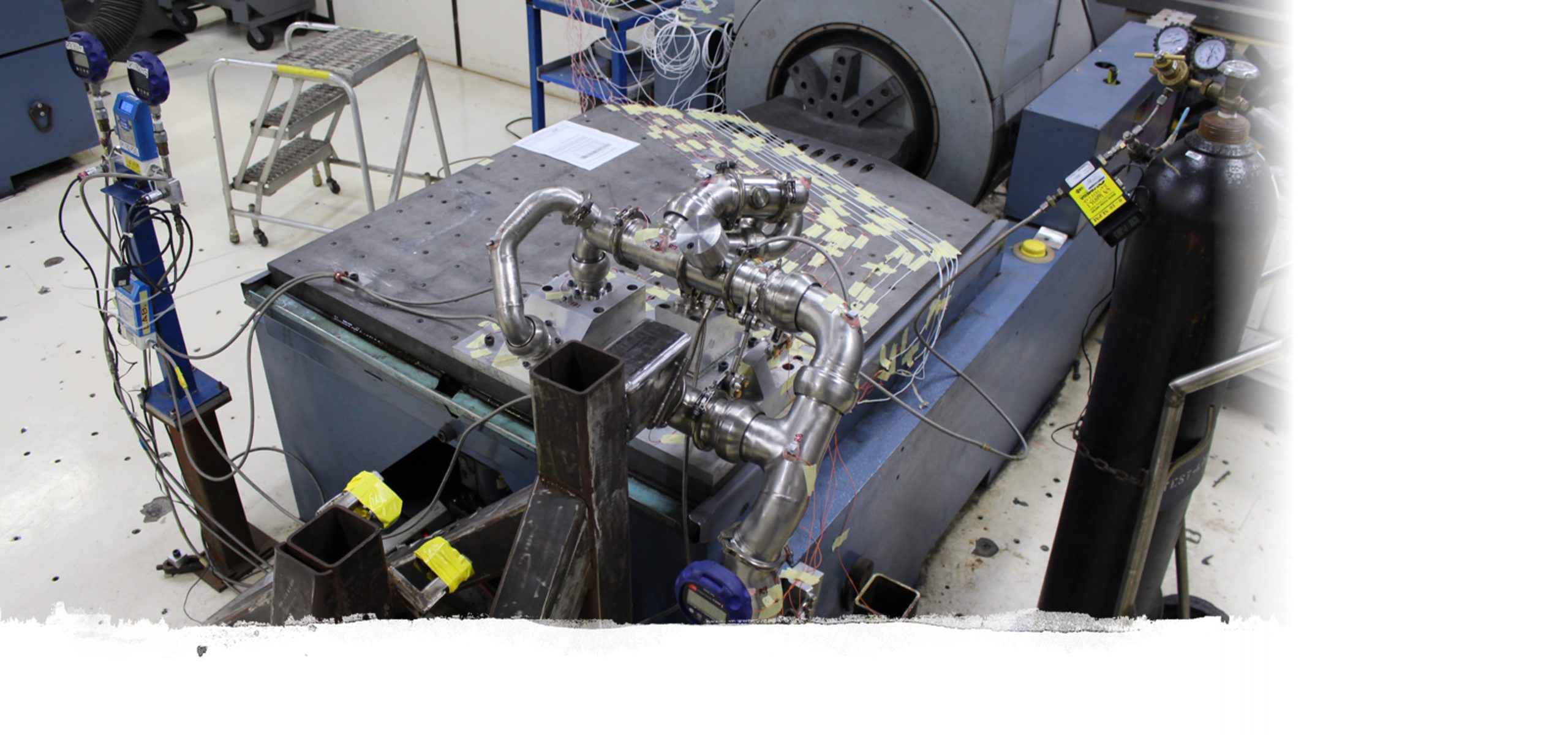

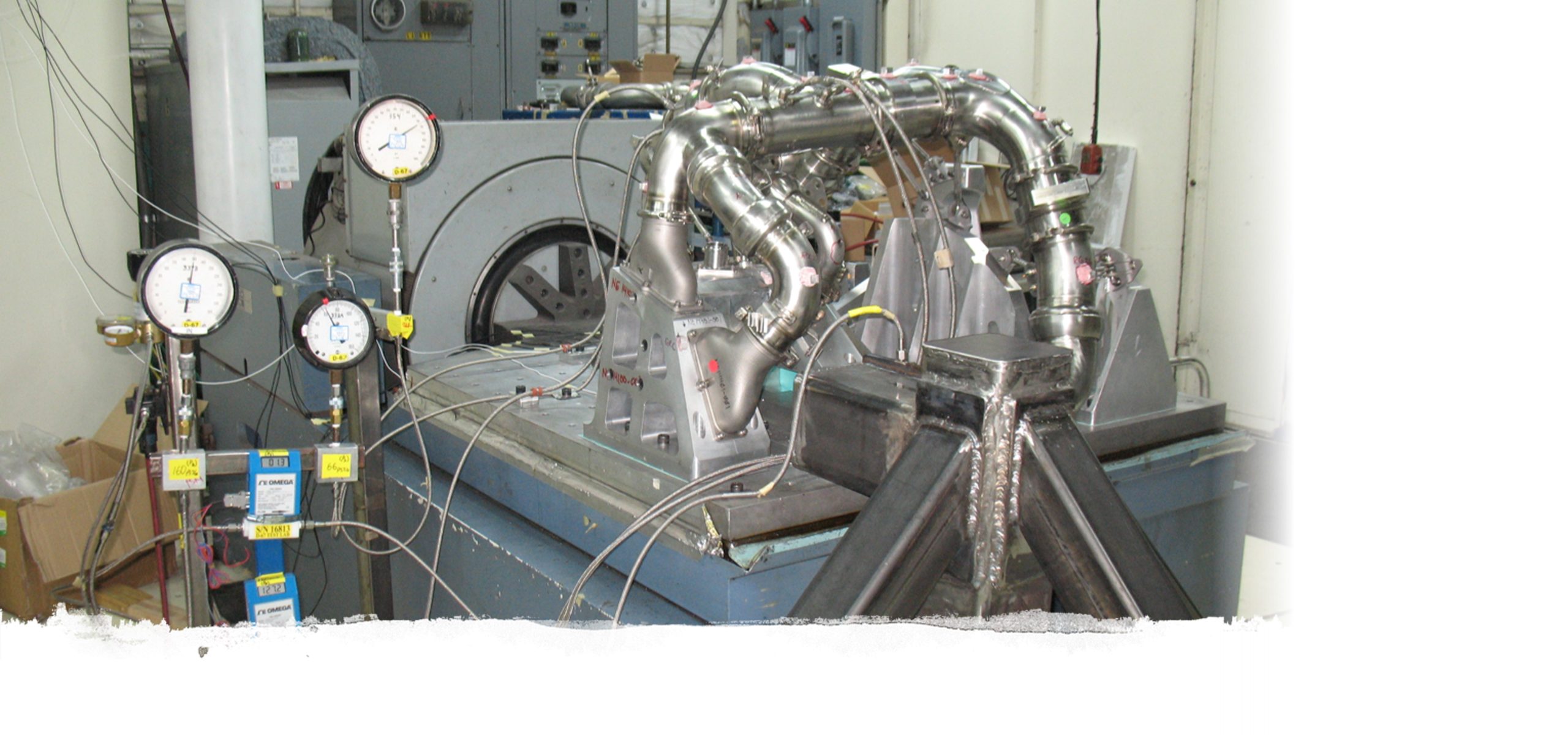

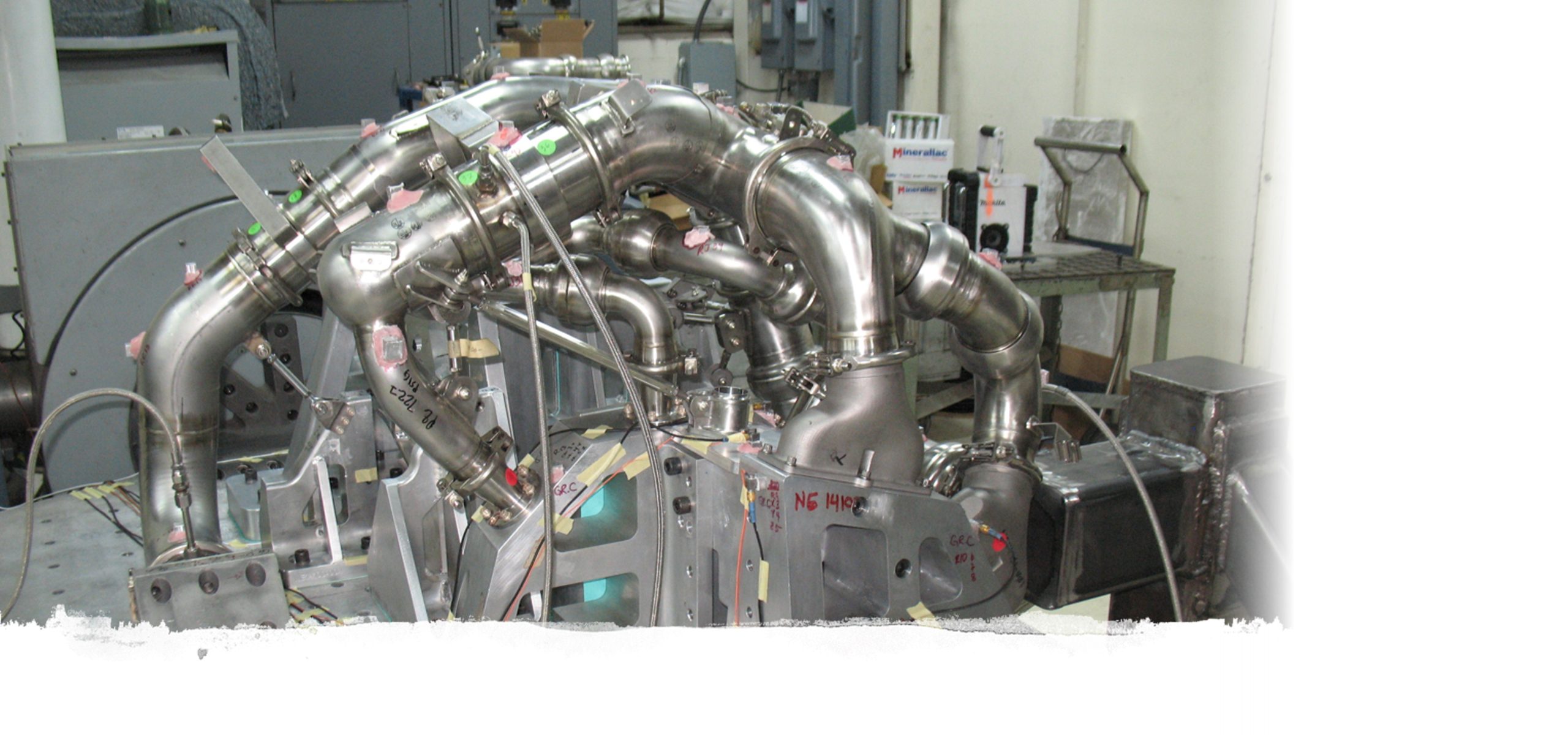

Humidity & Flow Testing

Temp/Humidity Chamber

– 32 cu.ft. (39” x 36” x 39”) Test chamber interior

– Temp range: -148 to 356°F

– Humidity: 10% to 98% RH

Continuous Gas Flow

– Max pressure: 650 psig (45 barg)

– Max flow: 2000 SCFM

– Heating capability: 1250°F at 80 SCFM

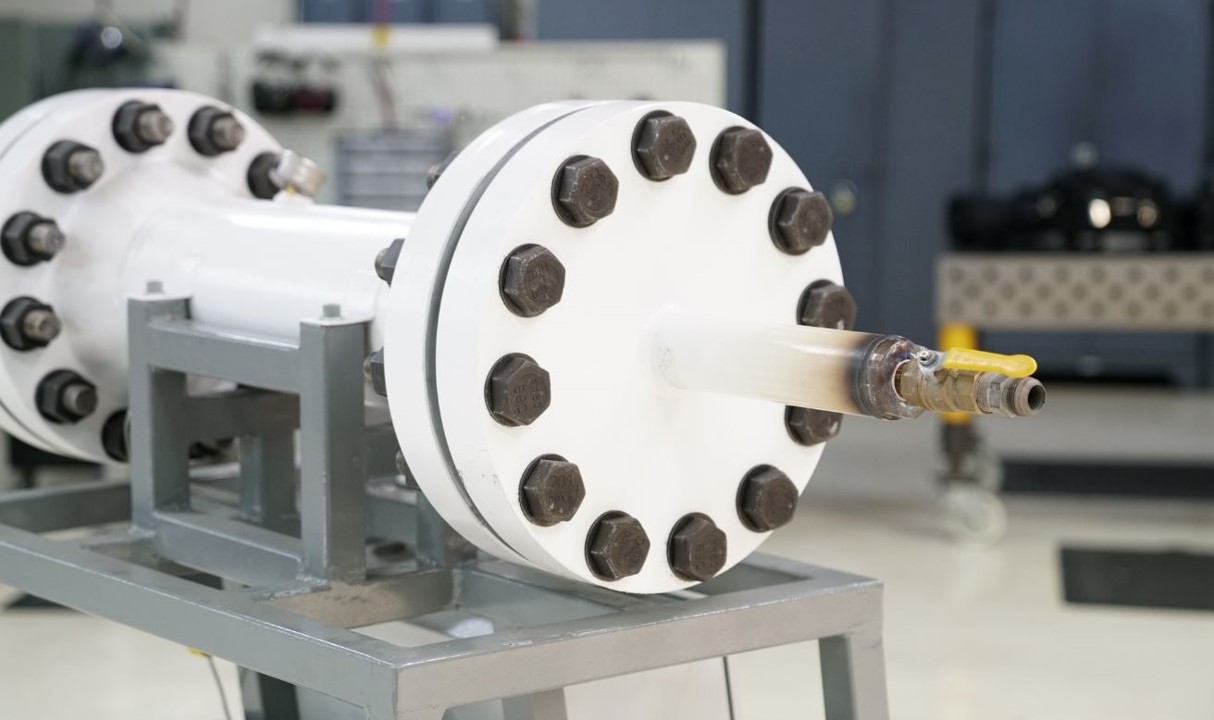

Static Pressure Testing

– Max pressure (water): 20,000 psig (1379 barg)

– Max pressure (GN2): 10,000 psig (690 barg)

High Temperature Oven

– 125 cu. ft. oven interior (5’ x 5’ x 5’)

– Max Temperature: 1300°F

Fire Testing

With over 15 years of fire testing experience, the SSP Engineering Lab is equipped to perform commonly sought fireproof and fire resistance testing on Aerospace components. Through the window in our fire test room, customers can view their component undergo flame exposure while simultaneously subjected to vibration per standard Aerospace requirements.

Fire test standards we typically test to include, but are not limited to, those defined in:

– ISO 2685

– AC 20-135

Tensile Testing

– Electromechanical test system with axial force-loading capabilities up to 67.4 kip (300 kN)

– Material testing to standards ASTM E8/E8M, ASTM B769, ASTM E9, ASTM E21, ASTM E238, and more

– High temperature testing up to 1000 °C

Fatigue Testing

– Servo hydraulic test system with dynamic axial force-loading capabilities up to 20 kip (89 kN)

– Material testing to standards ASTM E466, ASTM E399, ASTM E606/E606M, ASTM E647, BS EN 6072, and more

– High temperature testing up to 1000 °C