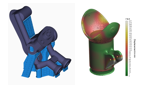

– Topology Optimization & Redesign Capabilities

– New Solutions to take advantage of the AM freedom

– Additive Build Setup and Simulation

– Microstructure Characterization

– Powder and Chemical Analyses

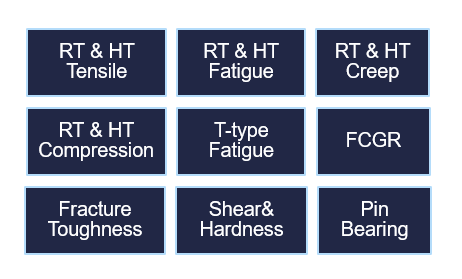

– Mechanical Testing

– Extensive dataset for AM Ti64 (MMPDS equivalent)

– Extensive dataset for AM IN718 (MMPDS equivalent)

– Ongoing characterization for AM SS 17-4

AM Production Cell

– EOS M400-4 Printer

– 400MM3 Build Volume

– 4 Lasers (4 Quadrants with Overlap)

– Double sided-recoating

– EOS IPMML Powder Station

– Closed system powder management

– Self contained Operators do not come into contact with powder during normal operation

– Powder re-use

– Sieves powder, stores in inert conditions

– Can serve up to 3 machines

– Vibratory Polisher and Band Saw

– Wire EDM and De-powdering system (WIP)

Senior Additive Powder Analysis Center

– Senior Additive has added capabilities to our ISO17025 certification to support the specific needs of AM.

– Senior Additive characterizes raw material and printed coupon properties and to ensure quality.

Senior Additive Mechanical Testing Center

MTS 100kN Landmark Testing System

Performs fatigue, fatigue crack growth, and fracture toughness testing at room and elevated temperatures (up to 2000°F)

MTS 300kN Criterion Material Testing System

Performs pin bearing, shear, tensile, compression, and creep testing at room and elevated temperatures (up to 2000°F)

Optimized Production Workflow

Senior Additive has established a fully integrated in house value chain for metal AM.

FEASIBILITY AND DESIGN ANALYSIS

AM INDUSTRIALIZATION

PRODUCTION

POST PROCESSING

VALIDATION

DfAM

Topology Optimization

Stress analysis

Build strategy

Support optimization

Process simulation

Laser exposure

Printing

De-powdering

Cleaning

Process monitoring

Stress relief

HIP*

Aging/Hardening

Support removal

Surface treatments

machining

3D Scan

FPI

Radiography/ CT Scan*

Material chemistry

Mechanical testing

Powder analysis

Quality System

SSP has added 32 new documents to its quality system specifically for AM process

– These procedures ensure proper traceability and part quality are maintained with the AM.

– SSP is one of the very few companies worldwide with Nadcap additive accreditation as a special process under Welding

– Senior Additive is an AS9100 Accredited Aerospace Manufacturing Site with an ISO 17025 Accredited Test Laboratory

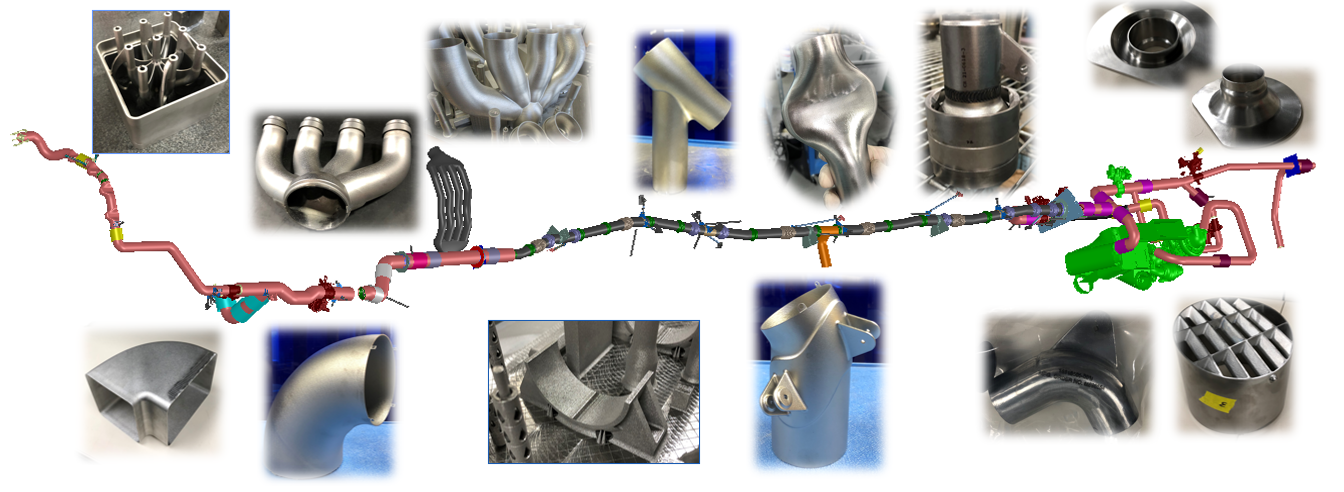

AM Integrated Bleed Air System (36 various AM parts)

Senior Additive’s capabilities have been effectively employed in production programs in a wide variety of bleed/ECS ducting applications

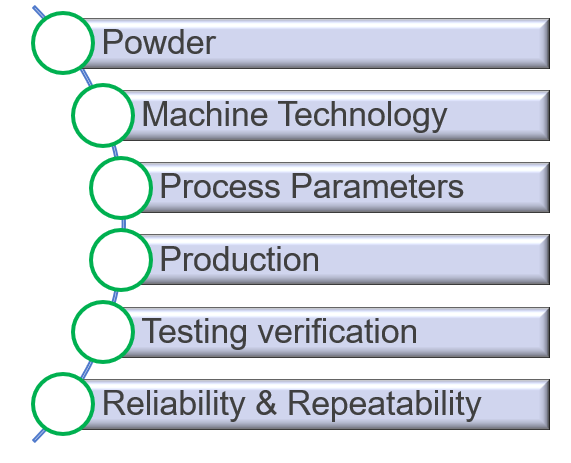

Senior Additive’s Frozen Process for AM

Understanding the relationship between material testing – AM processing -mechanical testing – performance ensures reliability and consistency in production.